THE MODERN SUPPLY CHAIN

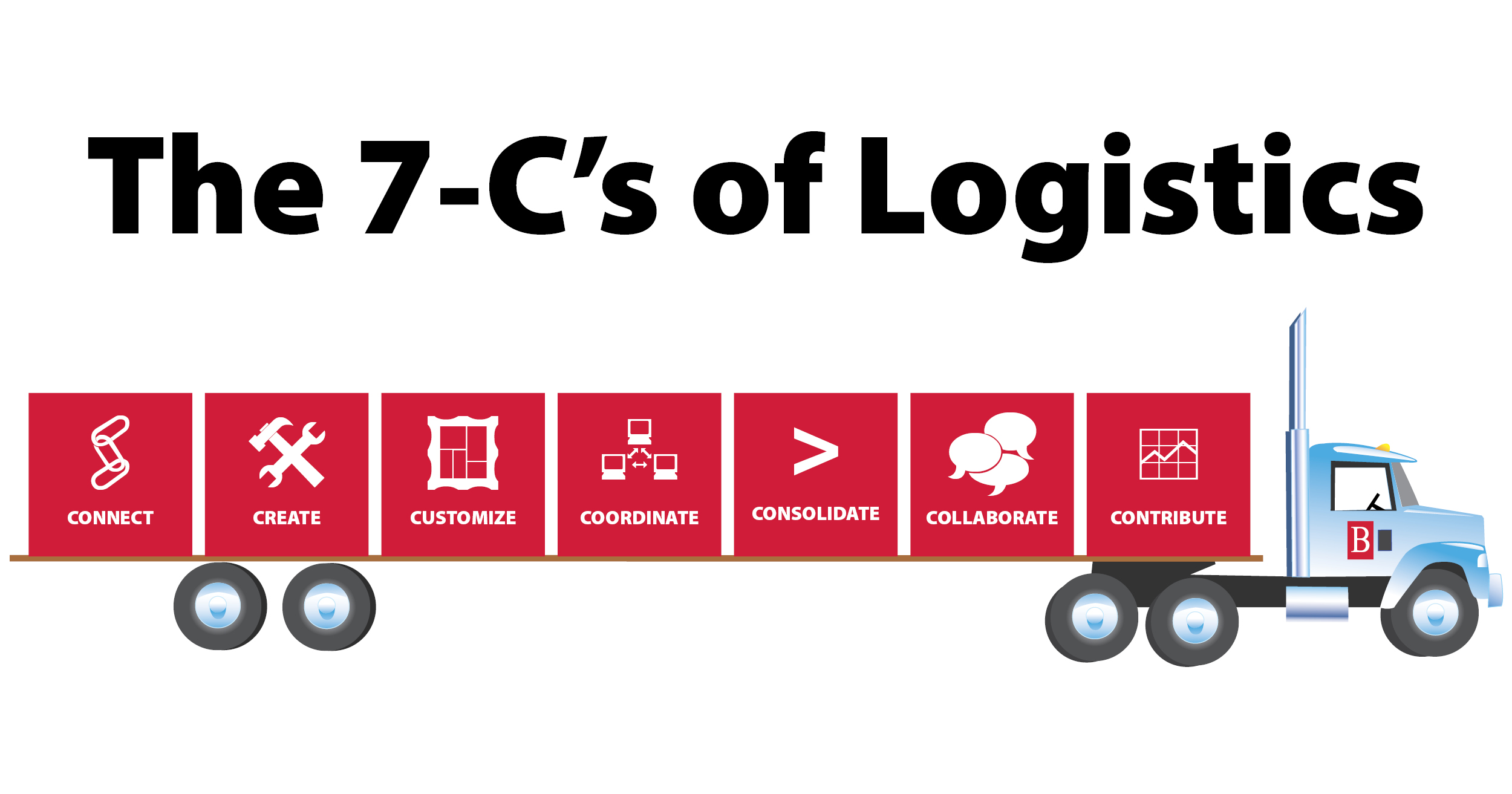

In the fast-changing logistics industry, professionals constantly work to manage the flow of goods and services in a way that meets demands for speed and efficiency. The 7-C’s of Logistics—Connect, Create, Customize, Coordinate, Consolidate, Collaborate, and Contribute—provide a useful framework for improving operations. These principles enhance the reliability, efficiency, and sustainability of supply chains, particularly as technology evolves and global events impact the sector.

Partnering with a professional logistics company is now essential for supply chain management as they help to navigate the growing complexities of modern logistics. Experts, like the logistical teams at Buchanan Logistics, simplify processes, lower costs, and improve collaboration among all parties involved. We adhere to the 7-C’s, which supports better coordination, consolidation, and communication, allowing our partner companies to respond more effectively to market needs and disruptions.

This article will take a closer look at the 7-C’s of Logistics and how they influence supply chain management. Each aspect, from communication to continuous improvement, plays a vital role in ensuring smooth operations and satisfying customer expectations. By understanding and implementing these principles, our logistics professionals can provide a stronger and more flexible supply chain.

THE 7-C’S FRAMEWORK

1. Connect: Establishing Strong Relationships in Logistics

Building strong relationships among stakeholders like suppliers, customers, and partners is vital for effective supply chain management. The rise of digital technology has changed how businesses interact with their supply chains, allowing for real-time communication and collaboration. Effective communication is key for both internal teamwork within organizations and for seamless external interactions. By keeping communication channels open, companies can quickly tackle potential issues such as delivery delays, quality problems, or sudden shifts in demand, which helps reduce disruptions.

Advanced technological solutions, such as real-time shipment tracking and user-friendly customer service tools like A.I. and chatbots, play a crucial role in strengthening these connections. The real-time tracking, that Buchanan utilizes, provides up-to-date information on shipments, allowing businesses to manage operations proactively, as delays can greatly affect costs and efficiency. Moreover, integrity within a company helps provide trustworthy answers to customer questions, promoting ongoing engagement and high customer satisfaction. Research indicates that 73% of customers are likely to spend less with a company they do not trust, underscoring the significance of strong relationships and integrity.

2. Create: Innovation and Efficiency in Logistics

In the changing world of supply chain management, encouraging innovation is crucial. We are dedicated to developing effective systems and processes that help us address the shifting demands of the market. By keeping up with industry trends and technological advancements, Buchanan constantly looks for ways to improve our logistics operations. Using modern tools such as artificial intelligence and advanced data analytics, we can forecast market trends, streamline logistics processes, and automate decision-making, which helps us stay competitive in the future of logistics.

Tackling key issues like underutilized trucking capacity is vital for enhancing operational efficiency and cutting costs. This innovative strategy can reduce logistics costs by as much as 20%. Optimizing truck capacity is not just an operational improvement; it is also a significant financial strategy that can turn challenges into opportunities for better profitability and sustainability.

Effective cost management is essential in logistics, requiring careful evaluation and optimization in different operational areas. By refining delivery routes, consolidating shipments, reducing claim and safety incidents, and negotiating advantageous contracts with carriers, we can better control transportation expenses. Furthermore, strategies like utilizing technology such as GPS for route optimization can greatly enhance overall efficiency and cost savings in the supply chain.

3. Customize: Ensuring Quality and Timeliness in Supply Chains

Customization is essential for addressing specific logistics needs. It is crucial to tailor logistics services to meet the distinct requirements and expectations of each client. As consumer demands evolve, logistics operations must focus on timely deliveries, precise tracking, and responsive customer service. Modifying services, such as changing delivery schedules and creating specialized solutions, can enhance efficiency and better meet customer needs.

To meet customer expectations, it is important not only to deliver products punctually but also to ensure quality throughout the entire supply chain. Quality control is vital and involves thorough inspections to reduce mistakes and maintain customer trust. Logistics professionals can enhance shipping routes and manage distribution centers effectively while quickly addressing any issues that arise. Customer feedback is crucial for driving enhancements, and ensuring that operations align with the shifting preferences of consumers.

4. Coordinate: Coordinating Complex Supply Chains

Coordinating complex, multi-tier supply chains is crucial for smooth logistics operations. This process includes managing the movement of goods and services through different stages, from suppliers to manufacturers, distributors, and ultimately to customers. It requires effective planning, advanced management systems, and careful attention to transportation, warehousing, and distribution. By effectively balancing customer demands, companies can prevent issues while encouraging teamwork among supply chain partners.

As supply chains grow more intricate and global, coordination challenges are likely to arise. Problems such as poor communication between suppliers and manufacturers can result in expensive delays. Furthermore, the need for flexibility to respond to changing market conditions, including seasonal demand shifts and global economic changes, adds to the complexity of logistics management. Strong communication and collaboration across the supply chain are essential for effectively addressing these challenges while ensuring operations remain balanced and efficient.

5. Consolidate: Consolidation in Supply Chain Management

Consolidation in supply chain management aims to simplify operations to improve efficiency and lower costs. This involves making the best use of resources like transportation, storage, and labor to meet operational needs effectively. For instance, companies might combine shipments to cut transportation expenses or merge logistics services to offer clients a comprehensive solution. As competition grows, businesses increasingly adopt consolidation methods, such as mergers and acquisitions, to take advantage of shared resources and skills.

Proper allocation of resources is essential for smooth logistics operations. Companies must carefully manage their transportation and storage capacities to respond to different supply chain demands, especially during busy seasons. This means increasing transportation resources during peak times, like holidays, and scaling back when demand is lower to keep costs in check. By balancing capacity and customer needs, businesses can improve efficiency and guarantee customer satisfaction, paving the way for long-term success.

6. Collaborate: The Key to Logistics is Collaboration

Collaboration plays a crucial role in the logistics industry, helping businesses utilize shared resources and skills to reach common goals and gain a competitive edge. By partnering with suppliers, partners, and even rivals, companies can combine their strengths to create innovative solutions. As we advance, technology will become an even more integral part of collaboration. This allows employees to focus on strategic projects, improving teamwork and driving success throughout the industry.

Continuously refining logistics processes is essential for boosting efficiency, cutting costs, and enhancing overall performance. Regular evaluations of current methods can identify inefficiencies and simplify operations, while comparing practices against industry standards helps maintain competitiveness. Implementing new technologies, such as artificial intelligence is key for ongoing improvement. A.I. can optimize supply chain processes, thus enabling real-time tracking of goods, increasing visibility and minimizing delays.

7. Contribute: Contribution is Essential for Enhancing Operational Value

Modern transportation management has transformed this area by providing a wide array of features that tackle significant logistical challenges. Plus businesses are increasingly focusing on making a positive impact on their industry, society, and the environment. This involves using newer trucks and making smarter decisions. By prioritizing these initiatives, companies can improve their brand perception while achieving long-term success in a competitive landscape.

However, making a positive contribution also means addressing complex regulatory standards. Adhering to import and export laws, environmental regulations, and industry-specific requirements is crucial for smooth logistics operations. Keeping up-to-date with regulatory changes, such as new tariffs or environmental guidelines, enables businesses to adjust their processes and reduce legal risks. By welcoming these changes and following compliance guidelines, logistics operations can remain efficient and avoid interruptions, underscoring their dedication to responsible and sustainable supply chain practices.

How The 7-C’s Affect the Future of Logistics

The 7-C’s of Logistics—Connect, Create, Customize, Coordinate, Consolidate, Collaborate, and Contribute—provide a valuable guide for today’s supply chain management. By focusing on these key concepts, logistics professionals can effectively manage the complexities of supply chains, ensuring prompt deliveries, maintaining product quality, and enhancing customer satisfaction. Moreover, emphasizing collaboration and contribution leads to operational success and promotes sustainable practices that meet societal expectations. As businesses prepare for the future, adopting the 7-C’s will be crucial for building resilient supply chains that can handle disruptions and respond to changing market needs. While the path ahead may be challenging, a commitment to these principles enables organizations to create lasting value and foster a sustainable future in logistics.

Resources

Check out our company overview ebrochure: Buchanan Logistics Digital Brochure

Contact us now to get more information

or to get a rate quote for your next project.

Logistics Insights & Industry Trends

Behind the Scenes: What It Really Takes to Keep Freight Moving | 30 Fascinating Facts About Logistics & Trucking | 10 Benefits of Partnering for Mining Equipment Transport | CVSA Roadcheck 2025: Ultimate Guide | Seamless Automotive Logistics Across North America